![]()

6YL---130型螺旋榨油機

MODEL6YL---130 SCREW OIL PRESS

一.主要性能參數:

Main Specifications

1,榨軸轉速:35-39轉/分

Shaft speed:35-39r/m

2,齒輪箱傳動比:15/381552=1:8.78

Gear ratio in gearbox: 15/381552=1:8.78

3配用動力:15-18.5KW

Motor:15-18.5KW

4三角帶:B型

Belt: B型

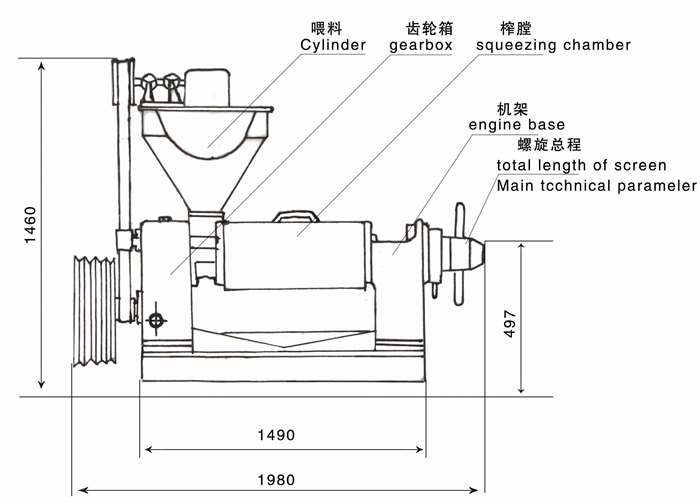

5外形尺寸:長x寬x高1980x680x1460(mm)

Outer dimension: L×W×H(mm) 1980x680x1460

6單機重量:760kg

Weight:760kg

7生產能力見表(一)

Capacity see table (1)

Table(1)production capacity

|

油料名稱

raw material |

每24小時處理量(噸)

feeding per hour(t) |

每百公斤產油量(kg)Oil output per 100kg raw material |

干餅殘油率(%)

residue(%) |

|

|

菜籽

rape seeds |

熱榨

Hot pressing |

9-12 |

30-38 |

7.5-8 |

|

冷榨

Cold pressing |

5-6 |

28-35 |

|

|

|

花生

Ground nuts |

熱榨

Hot pressing |

9-12 |

35-45 |

7 |

|

冷榨

Cold pressing |

5-6 |

32-40 |

|

|

|

大豆

Bean |

熱榨

Hot pressing |

9-11 |

10-16 |

6.5-7 |

|

冷榨

Cold pressing |

4.5-5.5 |

8-14 |

|

|

|

橄欖

olive |

熱榨

Hot pressing |

9-12 |

27-33 |

6 |

|

冷榨

Cold pressing |

5-6 |

25-30 |

|

|

|

棉籽

Cotton seeds |

冷榨

Cold pressing |

5-7 |

10-14 |

5.5-6.5 |

注:以上參數是指清選,分離,軋胚輔助設備齊全,工藝合理,操作正常是能達到指標。

Note : Figures shown above reflect performance when selecting ,separating,auxiliary facilities are available when manufacturing is rational.

二,工作原理與構造:

1,工作原理:

榨油機運轉時,將處理好的料胚帶如料斗,油料從料斗進入榨膛。有榨螺的螺旋向里推進,進行壓榨。

因料胚在榨油機的榨膛內是在運轉狀態下進行的,在榨膛高壓的條件下,料胚和榨膛之間產生很大的摩擦阻力。這樣就能使料胚和料胚產生摩擦,造成相對的運動。另一放面,榨螺的根圓直徑是逐漸增粗的,當榨螺轉動時,螺紋使料胚即能向前推進又能向外翻轉,同時靠近榨螺螺紋表面的料層隨著榨軸轉動,這樣在榨膛里的每個料胚微粒都不是等速度同方向的運動。而在微粒之間也存在著相對的運動。有摩擦產生的熱量又滿足了榨油工藝操作上所必須的一份熱量,有助于促使料胚中的蛋白質熱變性,破壞了膠體,增加了塑性,同時也降低了油的粘性,容易析```````榨出油來,因而提高了榨油機的出油率。

2, Oration principle and structure

2.1 oration principle

When oil presses operating prepared material enters extruding chamber from the hopper and then moves forwards by the rotating pressing screw and is pressed. Under the high-pressure condition in the chamber ,friction between material and screw ,between material and chamber will be created ,which also creates friction and relative movement among material particles. On the other hand, root diameter of the pressing screw caries larger from one end to the other ,hence. When rotating ,it not only pushes particles moving forwards but turns them outwards as well ,meanwhile ,particles adjacent the screw will rotation along with screw’ rotating ,causing every particle inside the chamber to possess different speed. Therefore relative movement among particle creates heat which is necessary during manufacturing because of helping protein change property ,damage colloid ,increase plasticity ,decrease oil’s elasticity ,resulting in high oil productivity.

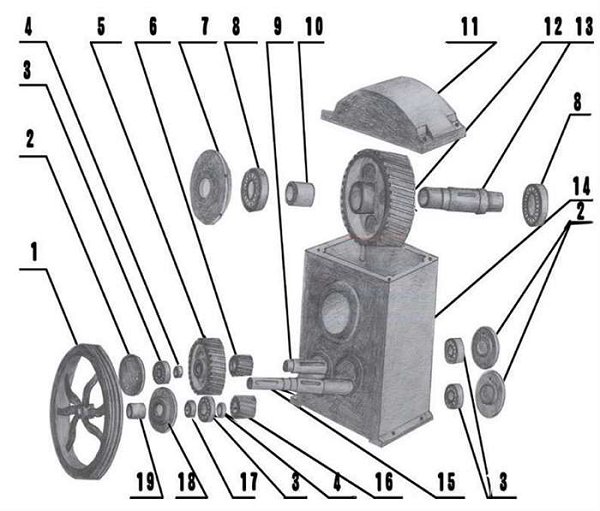

2.結構:該機有進料斗部分,齒輪箱部分,榨膛部分,榨螺部分,機架部分共五大部分組成:見圖(一)

圖一

三.機器的安裝:

榨油機安裝時必須在地腳螺栓牢固的安裝基礎上,使機體保持水平。電機安在進料斗的背面。

3.Installment

The oil press must be installed by bolts firmly on the foundation and be kept horizontal

四.機器的潤滑:

1.榨油機主要采用機油和黃油兩種形式潤滑。加油周期見表二

|

序號

NO |

潤滑部位

lubrication |

油脂種類

lubricate |

加油周期

Time span |

換油周期

Lubricate replacement period |

|

1 |

調節螺栓

Adjusting bolt |

20號機械油

Mechanical oil NO.20 |

每班2次

1-2time/day |

|

|

2 |

傘齒輪

Bevel gear |

20號機械油Mechanical oil NO.20 |

每班2次

1-2time/day |

|

|

3 |

軸承座套

Bearing bush |

20號機械油Mechanical oil NO.20 |

每班2次

1-2time/day |

|

|

4 |

齒輪箱

Gearbox |

20號機械油Mechanical oil NO.20 |

首次加油12kg

First time 12kg |

六個月

Every 6 months |

|

5 |

各滾動軸承

bearing |

潤滑油

grease |

|

每年一次

Each year |

4.Lubrication

4.1 Oil press is lubricated by lubricating oil and grease, see table(2)

五.機器操作:

(一)開機前的要點:

1.開機前先將齒輪箱內加注12公斤機油.

2機器安裝好后,按規定加注潤滑油,檢查各零部件是否緊固,操作手柄,插板是否靈活.

3.用手搬動大皮帶輪查機器有無松動或卡機現象,若有異常及時排除.

4.調整皮帶的松緊度,啟動電機,檢查槽輪方向是否與標志方向一致.

5檢查準備工作做好后,松開緊鎖螺母把榨螺擰到死點,再退回3-4圈,再前進半圈,保證榨螺與出餅口的間隙.

5.1 preparation before operating

5.1.1 12kg of lubricant needs to be filled into the gearbox.

5.1.2 After installing the machine, check whether lubricant has been filled in, bolts have been tightened, and handles are operable.

5.1.3 Check large pulley whether it is loose or blocked ,repair it if necessary.

5.1.4 Adjust the tightness of the belt ,switch on the motor and check its rotation direction.

5.1.5 Loosen the lock nut and tighten the screw to its end, then loose it for3-4circles and then tighten it again for half circle to assure the gap of the residue cake outlet.

(二)開機:

1,啟動電機,開動機器,將餅加入6%-8%水分,倒入料斗,磨光榨膛,進料不可過猛,否則可能造成榨膛堵塞與卡死機器事故,因此開始下料應該緩慢均勻,待榨膛磨光后,正常出餅后,方可將料胚倒入料斗.

2.運轉后觀察出餅情況,如不出餅,將榨螺再退出1-2圈,如還不出餅,應停機檢查.切記杜絕開帶車.故障排除后再行初榨工作.正常運轉時餅厚1-2毫米,餅成瓦片狀,手捏不粘,內面光滑,外面發皺,表面不帶油跡.

餅厚的調節:搬動調節螺旋上的手柄,將調節螺栓順時針旋轉,螺栓往外,餅就厚,反之餅就薄了。(調節螺栓為左T165x6)出餅圈與出渣稍頭的錐角不同,每轉一圈較餅厚度變化為0.4-0.5毫米。

3.榨油機運轉中,應經常檢查出油,出渣情況,正常時油大部分從條排與前幾節園排流出。如餅碎成渣,說明胚料太干。如發現餅發熱(散出蒸汽)成大片狀說明水分太高,應及時進行調節胚料水分的含量。

出渣:條排出渣時成細片狀說明水分高,如出粉狀含沫說明水分低。園排渣過多屬壓緊螺母未壓緊圓排,應上緊壓緊螺母,如水分合適,則條排不出渣或少出渣,圓排少量出渣也是允許的。料胚含水分的高低直接影響出油率,因此壓榨時應控制好料胚的水分。

5.2 operation

5.2.1 Feeding must be steady and slow at the beginning to avoid blocking

5.2.2 In the case no cake is extrude outward,return back the screw for 1-2circle 。If there is still no cake is observed,machine needs to be shut down and checked ,However, in any case, operating the machine backward is absolutely prohibited normally ,cake looks like tile but not sticky ;thickness is 1-2mm ,inner side is smooth ,out side creases and no oil the surface is allowed.

Cake thickness adjustment: Rotating the adjusting handle clockwise will make the cake thicker, otherwise will make it thinner. Each circle of adjustment(by adjustment bolt left hand T 165x6)will change the thickness 0.4-0.5mm.

5.2.3When machine is operating, oil extruding and residue outlet need be checked

Frequently .Normally, most of oil will flow outward from square rods and several front round plates. Broken cake residue indicates the material is too dry ; steam emerging from the cake residue indicates that it is too wet ,In any case ,water content in the raw material must be adjusted from time to time.

Slag slice emerging indicates too much water content and power-like slag low water content .Loose round plates will cause too much slag flowing outwards. However ,adequate water content will cause slag flowing outwards from square rods, little slag from round plates is allowed. In a word ,water content affects oil output rate , it needs adjusting properly.

(三)停機:

1.正常停機應將料胚全部榨彎,反復將榨螺退進數次,將榨膛中語料 走完,將出餅放至最后,然后停車.

2.停電或因其它事故突然停車,先切斷電源,抽出放料擋板, 用人力反轉大皮帶輪,使心軸反轉時退出料胚,立即將榨螺軸推出榨膛(當人力反轉大輪困難時,不得強制進行.以免損壞機器),進行清理.若抽不出來,應將壓榨螺母松動,要把上榨籠拆釣,用螺絲刀逐個將圓排松動,清理,未經清理不得再行開車.

5.3 stopping

5.3.1Repeatedly move screw forwards and backwards for several times and let all material resided in the chamber goes out and adjust the cake to the possible thinnest, then stop the machine.

5.3.2 When machine stops caused by any accident, power supply must be shut down first, then rotate large pulley manually backwards, let the material return out . Then pull out the shaft and clean it. In the case the shaft could not be pulled out, remove the upper case and loose lock nut, separate round plates and clean them one by one.

六.機器的主要零部件拆,裝:

1.主要零部件的拆裝方法:

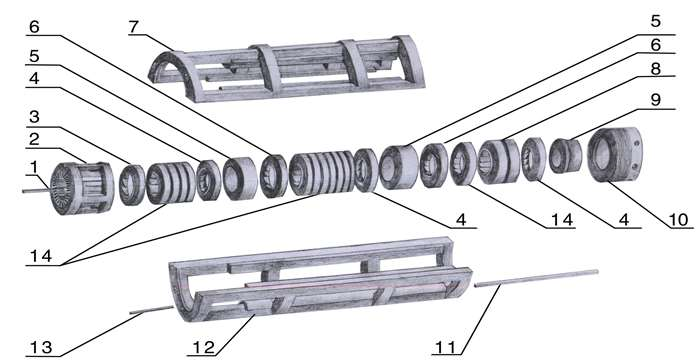

(!)榨籠(包括圓排、條排骨圈)的拆裝方法:

旋轉榨螺軸,將榨螺 從榨膛內抽出,然后用直徑24毫米粗的鐵棒插入出餅端壓緊螺母的孔內,逆時針方向旋轉松動螺母:松動上榨籠兩端4個M16的連結螺釘,卸掉連結上下榨籠的12個M16的螺栓,拆去上榨籠即可將圓排圈取出。見圖二

圖圖二

|

標號

Item |

零件名稱

Description |

每臺數量

Q’ty per set |

標號

Item |

零件名稱

Description |

每臺數量

Qty per set |

|

1

|

條排

Pressing bar |

30 |

8 |

20#21#圓排

Pressing ring NO.20、21 |

2 |

|

2 |

條排圈

Rails group ring |

1 |

9 |

出餅圈

Cake output ring |

1 |

|

3 |

1#圓排

Pressing ring NO.1 |

1 |

10 |

壓緊絲

Pressing bolt |

1 |

|

4 |

6#16#22#圓排

Pressing ring NO.6、16、22 |

3 |

11 |

榨籠長鍵Pressing cage major key |

1 |

|

5 |

7#圓排

Pressing ring NO.7 |

2 |

12 |

下榨籠

Bottom cage |

1 |

|

6 |

8#18#圓排

Pressing ring NO8、18 |

2 |

13 |

榨籠短鍵Pressing cage minor key |

1 |

|

7 |

上榨籠

Top cage |

1 |

14 |

2-5#、9-15#、19#圓排Pressing ring NO.2-5、9-15 19 |

12 |

注意:記住各圓排的位置,便于裝配。

(2)條排的拆裝方法:

卸下條排骨圈用鐵棒的一端從側面抵住一根條排,用手敲擊另一端,將一根條排打出,其余條排將自動松散下來.

(3)條排的裝配方法:

將條排圈立起,代出油槽面向下(建議下面放塊木板),把條排逐個的整齊的排列在內壁上。帶深油槽的一端朝下,兩個條排的深油槽面不能對著放在一起。最后一個條排用金屬棒打入》若條排松動,可以在條排之間加鐵皮,使條排緊貼內壁,達到用手摸內壁無突起現象為止。

(4)榨籠的裝法:

將條排圈有出油槽面面向機架,再按圓排序號依次放入圓排。帶出油槽面朝向機架。然后用壓緊螺母少上幾扣靠住圓排,在裝上榨籠。(上下榨籠均為配對制造,如更換需上下一齊換掉)用卸下的螺栓逐個交替上緊。

6.Maintenancen and Assembly/disassembly of Main parts

6.1 Assembly/disassembly of Main parts

6.1.1 Pressing case(round plates, square rods holder)

Rotate the screw shaft and remove it from the chamber. Loose the lock nut on the outlet end by rotating it counter-clock wise using a 24 mm diameter bar, loose four M14bolts, remove ten M16 bolts which are used to connect upper and lower cases. However ,after removing upper case, round plates and square rods holder can be pulled out.

6.1.2 Remove square rods:

After removing the holder, tap the end of one rod and take it out, then others will be easily removed.

6.1.3 Assembly of rods:

Erect the rod holder vertically and make its side with oil grooves locate downwards, better on a wooden plate, then put square rods to touch holders inner wall circumferentially with their grooves downwards again. However, grooves of every two adjacent rods should not be touched. Then insert shins(by a hammer)properly into rods gap to let than firmly touch rods holders inner wall. As a matter of fact, whole inner wall of rods should be smooth.

6.1.4 Assembly of the case:

Put the groove side of rod the holder to face the machine body, then insert round plates as per marks on them. Put lock nuts on to contact plates and then mount the upper case. Tighten bolts one by one.

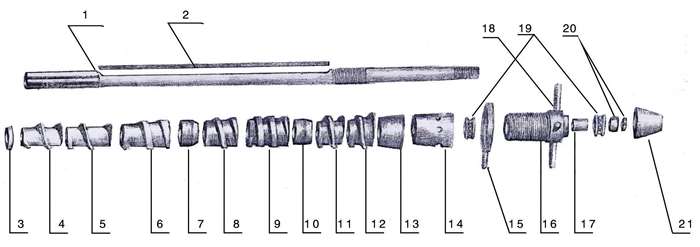

2.榨螺的拆裝方法:見圖三

(1)榨螺的拆法:停機后立即搬動手柄,把榨軸從榨膛內抽出,卸下保護帽、六方螺母、園螺母及調節螺栓,用直徑16的鐵棒插入鎖緊螺母的孔內順時針方向旋轉(切記與軸芯配合的螺紋均為左旋),拆去緊鎖螺母后,各節榨螺即可卸下。如榨螺(內孔進有細渣)因阻塞不好拆卸,可將地上墊一木板,二人將榨螺輕撞幾 下即可卸下,若仍卸不下來,可用木柴火加熱后再卸下。

(2)榨螺的安裝:將榨螺立起細端向上,裝上檔圈,在把榨螺由1號起依次裝于軸上,然后用鎖緊螺母壓緊,以防油渣深入榨螺孔內,影響榨螺的拆卸。(調節螺母使調節栓兩端是8309軸承,裝時兩軸承大孔面均靠在調節螺栓的兩端面。榨螺整體裝齊后用兩個(M42×2)的螺帽背緊,背緊時注意兩個8309軸承的縫隙 。用手搬轉調節螺栓,感到轉動靈活時即可。

6.2 Pressing screw:

6.1.1 Disassembly of the screw :rotate the handle as soon as machine stops and pull out the screw from the chamber ,remove nuts and adjusting bolt. Insert a 16mm diameter bar into lock nut and turn and turn it clockwise.(important note: left hand screw).After taking off lock nut, each part of pressing screw can be removed. However, holes in the screw might be blocked by fine slag particles, which retard the disassembly. Tapping or heating pressing screw might help disassembling.

6.1.2 Mounting pressing screw :put small end of its shaft upwards, mount the first screw and then the second...sequence, tighten then by the lock nut to avoid particles in . On both ends of adjusting bolt, which is easily swung on the shaft by adjusting nut, two bearing 8309 are mounted. Be careful to make big hole sides of these two bearings touch adjusting bolts double ends. Finally , whole pressing screw will be tightened by two M42×2 nuts, But certainly, gaps of two bearings need to be carefully set. In fact, if hands can swing adjusting bolts smoothly, the adjustment is acceptable.

圖三

|

標號

Item |

零件名稱

Description |

每臺數量

Qty per set |

標號

Item |

零件名稱

Description |

每臺數量

Qty per set |

|

1 |

螺旋軸

Screw shaft |

1 |

12 |

9#榨螺

Worm NO.9 |

1 |

|

2 |

長鍵

Long flat key |

1 |

13 |

出渣稍頭

Cake guide ring |

1 |

|

3 |

檔圈

Intermediate ring |

1 |

14 |

鎖緊螺母

Press nut |

1 |

|

4 |

1#榨螺

Worm NO1. |

1 |

15 |

緊定螺母

Tight nut |

1 |

|

5 |

2#榨螺

Worm NO.2 |

1 |

16 |

調節螺栓

Adjusting bolt |

1 |

|

6 |

3#榨螺

Worm NO.3 |

1 |

17 |

含油套

Adjusting bolt bush |

2 |

|

7 |

4#榨螺

Worm NO.4 |

1 |

18 |

大手柄

Big handle |

4 |

|

8 |

5#榨螺

Worm NO.5 |

1 |

19 |

軸承(8309)

Bearing 8309 |

2 |

|

9 |

6#榨螺

Worm NO.6 |

1 |

20 |

圓螺母

End nut |

2 |

|

10 |

7#榨螺

Worm NO.7 |

1 |

21 |

保護帽

Safe cover |

1 |

|

11 |

8#榨螺

Worm NO.8 |

1 |

|

|

|

3.齒輪部件圖(圖四)

6.3 structure diagram of gearbox.

圖四

|

標號

Item |

零件名稱

Description |

每臺數量

Qty per set |

標號

Item |

零件名稱

Description |

每臺數量

Qty per set |

|

1 |

大皮帶輪

Big belt wheel |

1 |

11 |

齒輪箱蓋

Gearbox cover |

1 |

|

2 |

無孔軸承蓋

Gland |

3 |

12 |

52牙齒輪

Gear 52 teeth |

1 |

|

3 |

軸承(309)

Bearing309 |

4 |

13 |

空心軸

Hollow shaft |

1 |

|

4 |

隔套

Spacing collar |

2 |

14 |

齒輪箱

Gearbox body |

1 |

|

5 |

38牙齒輪

Gear 38 teeth |

1 |

15 |

齒輪箱長軸

Gearing major axis |

1 |

|

6 |

右旋15牙齒輪

Gear 15 teeth |

1 |

16 |

左旋15牙齒輪

Gear 15 teeth |

1 |

|

7 |

大壓蓋

Big gland |

1 |

17 |

油封

Oil seal |

1 |

|

8 |

軸承(217)

Bearing 217 |

2 |

18 |

有孔壓蓋

Gland with hole |

1 |

|

9 |

齒輪箱短軸

Gearbox minor axis |

1 |

19 |

小皮帶輪

Small triangle |

1 |

|

10 |

接套

Connecting bush |

1 |

|

|

|

七. 安全生產規則:

為了保證機器的正常運轉,避免機器人身事故的發生,請嚴格注意下列事項:

{C}1. 機器運轉中,禁止用手或金屬棒深入料斗內或撥弄出餅處的餅.

{C}2. 在開車前或機器運轉中,嚴禁將榨螺擰到死點,以導致出渣稍頭 和出餅圈接觸,相互摩損,造成機器事故.

機器的存放:榨油機若長期停放, 應除去表面油垢,清理各油部件油渣.涂防銹油,置于干燥處,榨籠用油布蓋豬,以免灰塵雜物入積條排、圓排縫隙,影響下次使用.

7. Safety

Following items are strictly requested to be obeyed.

7.1 During operating, hands or metal rods are strictly prohibited to enter the hopper to touch cakes.

7.2 Tightening the screw shaft to its dead end is prohibited before starting or during operating, which might cause slag outlet to contact cake outlet ring, resulting in wearing.

In the case of storage, oil dirt on machines surface and slags on each part need to be taken off. Paint

rust-resisting grease and keep in dry place. Case needs to be covered to prevent dirty foreign particles from entering.

八.影響出油的主要因素:

影響螺旋榨油機出油率的主要因素有一下幾點:

{C}1. 油料的水分:

影響出油率最關鍵的因素是油料的水分,油料中水分多或少都直接影響出油率.一般用戶沒有化驗設備,幾種主要油料的合適水分可按經驗方法確定如下:

(1). 大豆: 如果用門牙咬能咬碎, 用臼牙咬成扁諞狀, 具有裂紋, 有輕度的響聲, 則說明水分 合適.若成扁片狀, 但沒有裂痕, 則太濕; 可用火炕或太陽曬的方法進行處理. 若破碎并有很大的響聲,則太干;這時需要適量的水.

(2) 棉籽:用牙咬殼仁分離,殼破有響聲,則合適;若成扁形,則太濕。若殼仁成粉,則太干。

(3)菜籽:可用兩種方法分榨:冷榨或熱榨。

冷榨時:用指甲擠有響聲,分成兩片并有油擠出,為合適;成粉則太干,成粉則太濕。

熱榨時:需經炒,炒后檢查,用兩塊木板揉擦菜籽,殼與仁分離則合適:若仁成粉則太干;若殼與仁不分則太濕。

2. 出餅的薄厚,反映出榨膛的壓力大小;餅厚則壓力小,餅薄則壓力大。一般規律與圓排的松緊相似,即油料含油少壓力就應大,餅薄,圓排應壓緊(用壓緊螺母壓緊);油料含油多,則榨膛壓力應小,餅厚,圓排應松些。

餅比較合適的厚度為:

大豆: 第一遍壓榨應稍厚為1-1.5毫米左右:第二遍的厚應為0.5-1毫米左右。

棉籽:榨一遍即可,餅厚在1-2毫米左右。

花生仁:一般冷榨2-3遍,餅厚1-2毫米左右。

在榨油中,由于各種因素的不同,因此掌握出餅的厚度應根據出餅的情況,出油最旺時為合適餅厚。對上述餅厚度的確定數字決不能生搬厚度應根據出餅的情況,出油最旺時為合適餅厚。對上述餅厚度的確定數字決不能生搬硬套。

8. Factors affecting oil output rate

Following factors may affect oil output rate:

8.1 Water content:This is the critical factor,as a matter of fact ,water content directly affects oil output rate

However, user usually has not proper inspection equipment. Hence, water content of some main raw material may be detected as follows:

8.1.1 Bean: if teeth beating could crack it, forming flat pieces accompanied with light sound , the water content is suitable. Flat piece without cracking means too wet. Heating or sunshine may be drive water off. However, cracking accompanied with loud indicates too dry. Adequate water needs to be added.

8.1.2 Cotton seeds: shell and kernel may be separated by teeth beating. Shell breaking may be accompanied by sound, which means water content is suitable .shell being flatting indicates too wet, shell being splitted into powder means too dry.

8.1.3 Rape seeds: They can be pressed either at hot or at cold state.

Cold pressing: extruding by finger, if they splitted into two pieces, accompanied by sound and oil, this implicates water content is adequate. Otherwise, extruding makes power indicates too dry; makes flat slice, too wet.

Hot pressing (after heating) : To scratch seeds by two slices of wood, if shell and kernel could be splitted, water content is adequate. If kernel becomes power, it is too dry; in the case that shell and can be splitted, it is too wet.

{C}8.2 Cakes thickness reflects the pressure inside the chamber. Thicker cake indicates lower pressure inside the chamber; thinner cake-higher pressure inside. If raw material has less oil content, chamber pressure should be higher, cake will be thinner, round plates need to be tightened; in the case of high oil content material, pressure in the chamber should be lower, then circular plates need to be loosened, resulting in thicker cake. Recommended thickness of cakes will be.

Bean: 1.1-1.5mm for the first pressing ;0.5-1mm for the second pressing.

Cotton seeds : only one pressing , 1-2mm.

Ground nut kernel : Normally cold pressing for 2-3 times , 1-2mm

Important note: cakes thickness should be as according to different factors to achieve highest oil output rate. Hence, above figures will only be for reference.

九.一般故障及其排除方法

9. failures and removal

|

序號 |

故障 |

產生原因 |

排除方法 |

|

1 |

突然停車,榨螺軸卡死。 |

{C}1. {C}新機初榨,沒通過磨合大量投料入榨。

{C}2. {C}餅的厚度太薄,榨膛壓力增大。 |

1.按說明方法操作,經常注意機器的聲音及電流強度的大小。 |

|

2 |

出油過底 |

{C}1. {C}油料水分不合適。

{C}2. {C}榨膛溫度 低。

{C}3. {C}條排,圓排間隙不符合要求。

{C}4. {C}零件磨損。 |

{C}1. {C}按說明書操作。

{C}2. {C}松或緊動壓緊螺母,使其少量出渣,流油暢通。 |

|

3 |

入料斗存油(返油) |

1.圓排條排過緊。

2.油料含油過多,餅出的太薄。 |

1.松動壓緊螺母使其流油暢通。

2.調節出餅厚度,將餅加入榨膛把油沖出。 |

|

4 |

餅代油斑 |

{C}1. {C}油料水分過多。

{C}2. {C}圓排間隙過小。

{C}3. {C}零件磨損。 |

{C}1. {C}按說明書操作。

{C}2. {C}松動壓緊螺母加大圓排間隙。

{C}3. {C}更換新零件。 |

|

5 |

油質暗褐而綢 |

{C}1. {C}榨膛溫度低。

{C}2. {C}油料雜質過多。

{C}3. {C}油料過干或發霉。 |

{C}1. {C}按說明書操作

{C}2. {C}篩選油料。 |

|

6 |

產量低 |

{C}1. {C}壓榨未經脫絨的棉籽,絨長易于搭橋,纏軸。

{C}2. {C}榨膛,榨螺不光滑。

{C}3. {C}油料含水分過多。

{C}4. {C}出餅口間隙過小。

{C}5. {C}棕螺磨損。 |

{C}1. {C}棉籽脫絨或經篩選。

{C}2. {C}在更換新件后要進行一段時間的磨合使榨螺光滑。

{C}3. {C}按說明書操作。

{C}4. {C}更換新零件。 |

|

7 |

不入料 |

{C}1. {C}含油多的油料返油。

{C}2. {C}油料太濕(尤其是棉籽) |

{C}1. {C}按說明書操作。

{C}2. {C}棉籽要脫絨。 |

|

8 |

嚴重冒渣 |

{C}1. {C}條排,圓排間隙過大。

{C}2. {C}榨膛壓力過大。

{C}3. {C}零件磨損。

{C}4. {C}油料太干。 |

{C}1. {C}按說明書操作。

{C}2. {C}更換新件。 |

|

NO |

Failures |

Reasons |

Removal |

|

1 |

Sudden stop, shaft blocked |

{C}1. {C}New machine without running up.

{C}2. {C}Cake too thick, pressure too high. |

1.Carefully operating as per the manual.

2.Note motor sound and current value |

|

2 |

Low oil output |

{C}1. {C}Non-adequate water content.

{C}2. {C}Low chamber temperature.

{C}3. {C}Non-adequate gap among rods or plates.

{C}4. {C}Parts worn. |

1.Operating as per the manual.

2.Loosen tightening nut to drive slag off.

3.Replace worn parts. |

|

3 |

Oil return to hopper |

{C}1. {C}Too tight rods and plates.

{C}2. {C}high oil content and thicker cake. |

1.Loosen tightening nut。

2.Adjust cake thickness and add cakes into chamber to drive oil off |

|

4 |

Oil spot on cakes |

{C}1. {C}Too much water content .

{C}2. {C}Too small gap among rods and plates.

{C}3. {C}Parts worn |

1.Operating as per the manual

2.Loose tightening nut.

3.Replace worn parts |

|

5 |

Dark and viscous oil |

{C}1. {C}Low chamber temperature.

{C}2. {C}Too much forming particles in oil .

{C}3. {C}Raw material too dry. |

1.Operating as per manual

2.Selecting raw material |

|

6 |

Low productivity |

{C}1. {C}Poor quality of cotton seeds.

{C}2. {C}Chamber and pressing screw not smooth.

{C}3. {C}Raw material too much water content .

{C}4. {C}Too much gap at oil outlet port.

{C}5. {C}Worn screw |

1.Cotton seeds selected.

2.Make chamber and screw and smooth.

3.operating as per manual

4.replace worn parts |

|

7 |

Raw material can be fed |

{C}1. {C}Oil returns to hopper.

{C}2. {C}Wet raw material . |

1.operating as per manual

2.cotton seeds prepared |

|

8 |

Cracked residue appears at the outlet severely |

{C}1. {C}Gaps among rods and plates too big

{C}2. {C}Too high pressure in the chamber.

{C}3. {C}Parts worn.

{C}4. {C}Raw material too dry. |

1.operating as per manual

2.replace worn parts |

十.主要油料的壓榨方法:

1. 大豆的壓榨方法:目前大豆的壓榨方法主要有兩種,分熱榨或冷榨.

(一)冷榨工藝流程:

大豆----篩選----壓榨(水分合適)

(二)熱榨工藝流程:

大豆----篩選---軋胚----蒸炒----壓榨

生產工藝說明: 先將大豆篩選除雜,再將大豆破碎加水約7-8%進行軟化,進入蒸鍋蒸至115度左右方可入榨.

2.菜籽的壓榨方法:菜籽分冷榨或熱榨,為了提高出油率和油品的質量,一般以熱榨為主.

其工藝流程如下:

冷榨: 篩選----軋胚----壓榨

熱榨: 篩選----軋胚----蒸炒-----壓榨

冷榨: 先將菜籽篩選去雜,再檢查菜籽的含水量,無檢查設備的前提下可以用土法檢查:用指甲將菜籽擠一下,若有響聲,并分成兩片,或有油擠出最為合適,若成粉則太干,若成餅則太濕.若太干要加2.5-3%的水,待炒籽達到棕黃色,溫度110-120度最為合適,方可入榨.

{C}3. 花生仁的壓榨方法: 花生仁熱榨或冷榨均可,以熱榨為主(冷榨效果不如熱榨). 熱榨時先把花生仁粉碎或榨胚,然后放在蒸鍋內蒸1.5-2小時,溫度達120度左右,含水3%左右,即可入榨,榨油機溫度達85度時,開始正常壓在榨如 無蒸鍋,也可將花生仁放在炒鍋內炒,先將花生仁粉碎,逐漸加大約7-8%的水,炒至深黃色時,即可出鍋入榨。

{C}4. 帶殼花生的壓榨方法:帶殼花生的壓榨,花生干濕必須合適,一般剝去花生的外殼,花生仁可以用手搓去紅皮壓榨,花生壓榨兩遍即可,花生過濕,壓榨時產生響聲,應將花生重新烘干或曬干。如榨帶殼花生出餅不順利,加大約20%的餅與花生半均后再入榨。

10.Extruding methods of several raw material.

10.1 Bean : two ways , cold and hot extruding.

(1) Cold extruding :bean-selecting-pressing (in case of adequate water content).

(2) Hot extruding : bean-selecting-per-pressing-heating(steaming etc)-pressing.

Firstly, selecting beans and remove foreign particles, then soften by breaking and adding water of 7-8%,and then steam them to 115C; beans will be ready for extruded.

10.2 Rape seeds: also, cold and hot extruding for your choice, but normally hot extruding is recommended.

Cold extruding : selecting –pre-pressing.

Hot extruding: selecting –pre –pressing-heating(steaming etc)-pressing.

When hot extrusion, to remove foreign particles by selection ,then check water content as described above; in case of too dry, add 2.5-3% of water. Normally two times extruding is enough.

When cold extrusion, after selecting , to pre-press and heat them, During heating, add2-3%of water and await till look coffee color and temperature 110-120C, then ready for pressing.

10.3 Groundnuts kernel, cold and hot extrusion are both available ,yet prefer hot pressing. When hot pressing ,firstly crack or pre-press, then steam for 1.5-2 hours, temperature about 120C.water content 3%will be good. Normal pressing starts at temperature of 85C. or crack them firstly and at a pot, add 7-8%

of water, look coffee color will be ready for pressing.

10.4 Groundnuts: remove shell first and remove red peel of the kernel ,then press for two times, Sound indicates it is too wet and need drying. In the case of poor cake moving out, mix about 20%of with them may help.

掃一掃

獲取更多快速服務

全國免費咨詢熱線

15639480959

掃一掃

獲取更多快速服務

全國免費咨詢熱線

15639480959